LIGH2T: Large-Scale Integrated Gas H2 Fiber Optical Sensor and Detector

Green hydrogen will play an essential role in the energy transition. But monitoring and managing leaks during the production and storage of this highly volatile and flammable gas is essential. Given the expected exponential growth in green hydrogen production, TNO has developed an affordable, scalable, flexible, and multi-point measurement solution for leak monitoring and management.

The need for solutions

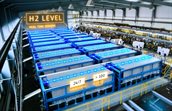

Green hydrogen production in Europe is expected to grow from 0.7GW today to 1,500GW by 2050. With production asset investment costs ranging from €1,500 to €2,000 per KW, this is a multi-billion-euro market. This expected exponential growth is driving producers, pipelines, fuel stations, and storage facilities to seek state-of-the-art solutions to monitor the inevitable leaks of this highly volatile and flammable gas. Preventing explosions, fires, and contamination will require a sophisticated network of leak sensors that detect leaks as early as possible and allow for efficient control. Current sensor solutions are expensive, difficult to scale, and challenging to manage.

Standard electrical leak sensors used in small-scale hydrogen production are not scalable to larger-sized production and storage facilities. The single-point electrical sensors are difficult to place nearby crucial leakage points, require large amounts of cabling, and the use of electricity in nearby sensor connections can introduce ignition risks. Each sensor must also be individually calibrated and maintained. In addition, the vast number of electrical sensors needed to secure a large facility would create excessive electrical noise that can interfere with sensor readings. The current H2 leakage sensor commonly used by the industry has a detection limit of 0.1% to 4% – a stage at which a leak already presents a significant danger, especially if the leak is not close to the sensor. Perhaps most importantly, managing a leak of this size requires the entire plant or facility to be shut down and controlled, halting the production of hydrogen entirely until the leak is addressed.

The TNO innovation

The LIGH2T sensors enable remote calibration and control of the entire sensor system. The technology platform also allows for multi-parameter readouts, measuring not only hydrogen levels, but also critical data points like pressure, temperature, strain, and more, to enable more accurate monitoring and calibration without additional equipment/systems. These long-lasting, less expensive sensors are highly scalable and affordable, and help ensure higher levels of stability and fewer shutdowns. Investment in the system is expected to create an optimal return on a facility’s CAPEX and OPEX expenditures, and ensure better ROIs due to fewer shutdowns. And the data the system collects provides crucial insights into facility operation and productivity.

Benefits beyond the norm

TNO’s unique, patent-pending sensor system was specifically designed for the most sensitive hydrogen sensing possible. Both the unique coating and the sensors themselves provide extensively more sensitive readouts than the current state-of-the art.

What’s more, the flexible fiber sensors enable large quantities to be installed in a larger facility with ease, and the non-electrical design ensures there is no risk of interference, jamming, or excessive power usage. The robust data collected by the sensors allows for smooth and comprehensive data acquisition and operating system management for smart grids and dynamic energy mix demands.

Partnering for impact

While the sensors have already been proven in laboratory settings, TNO aims to make adjustments and improvements to the technology in a real-life setting, to ensure the sensors fully align with industry needs and expectations. In addition to investors aiming to accelerate the energy transition, TNO is searching for partners and installation opportunities to test and fine-tune the technology in line with market needs. This phase of development will also help TNO refine requirements and specifications for the technology.

Could LIGH2T technology benefit your market position? Contact us for investment and/or development opportunities.